As industries continue to seek efficient and environmentally friendly solutions for surface cleaning, laser technology has emerged as the go-to method for rust removal and surface preparation. Rust-free laser cleaning is revolutionizing the way surfaces are treated, offering a non-abrasive, precise, and sustainable solution that outperforms traditional methods like chemical treatments and abrasive blasting.

If you’re looking for a reliable and advanced way to restore your surfaces, check out RenovateRX’s Rust-Free Laser Cleaning Services.

What is Rust-Free Laser Cleaning?

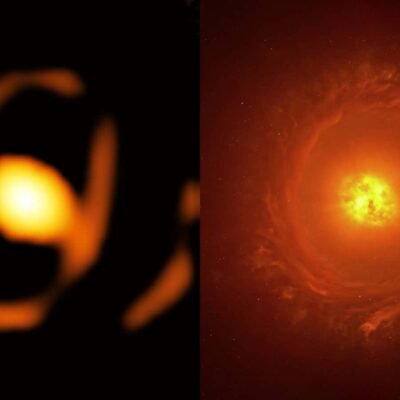

Rust-free laser cleaning is a process that uses concentrated laser beams to remove rust, contaminants, paint, and other unwanted layers from surfaces. The technology works by targeting and heating the surface impurities until they are vaporized or expelled. The result is a clean and polished surface without any damage to the underlying material.

Because laser cleaning can be finely controlled, it’s ideal for applications that require precision and care. This includes cleaning delicate machinery, preserving cultural artifacts, and preparing surfaces for coating or welding.

How Does Laser Cleaning Work?

The technology behind rust-free laser cleaning is known as laser ablation. In this process, a laser beam is directed at the surface, where it interacts with the contaminants. When the laser energy hits the material, it causes the rust or coating to break down and vaporize, leaving behind a smooth, clean surface.

The intensity, wavelength, and duration of the laser can be adjusted based on the material type and the level of contamination. This customization makes laser cleaning a versatile tool for various industries, from automotive and aerospace to manufacturing and even art restoration.

Benefits of Rust-Free Laser Cleaning

Rust-free laser cleaning has several advantages over traditional cleaning methods:

Non-Destructive: Unlike abrasive methods, laser cleaning does not harm the base material, preserving its integrity. This makes it ideal for cleaning sensitive components and high-value surfaces.

Environmentally Friendly: Laser cleaning is a dry process and does not require chemicals, solvents, or other consumables, making it eco-friendly and safe for operators.

Precision and Control: Laser parameters can be fine-tuned to target only specific layers, allowing for precise removal of rust, paint, or other contaminants without affecting adjacent surfaces.

Cost-Effective: While the initial setup costs might be higher, the long-term savings are significant due to minimal maintenance and consumable costs.

Versatility: Laser cleaning can be used on a variety of materials including metals, ceramics, and composites, making it suitable for numerous applications across different industries.

Automation-Friendly: Modern laser systems can be easily integrated into automated workflows, reducing labor costs and increasing overall efficiency.

Applications of Rust-Free Laser Cleaning

The versatility and precision of rust-free laser cleaning make it suitable for various applications:

Industrial Equipment Maintenance: Removes rust, grease, and paint from machinery and industrial tools without causing wear and tear.

Automotive and Aerospace: Cleans car frames, engine parts, aircraft components, and other delicate surfaces without altering their structural properties.

Surface Preparation for Welding: Prepares metal surfaces by removing oxides and contaminants, ensuring a high-quality weld.

Cultural Heritage Restoration: Safely cleans historical artifacts, sculptures, and artworks without damaging the underlying materials.

Paint and Coating Removal: Strips old coatings from surfaces like metals, wood, and plastics, making it ideal for refurbishing and repainting projects.

Electronics and Semiconductor Industry: Cleans delicate components without leaving any residue, reducing the risk of contamination.

Why Choose Rust-Free Laser Cleaning?

Choosing rust-free laser cleaning means opting for a method that prioritizes surface integrity, safety, and sustainability. It eliminates the risks associated with abrasive methods, such as surface scratching or weakening of the material, and avoids the use of toxic chemicals that pose health hazards to workers and environmental risks.

Moreover, laser cleaning systems are highly adaptable and can be tailored to meet specific cleaning requirements. Whether you need to restore a rusted car frame or prepare a delicate surface for further processing, laser technology offers unparalleled flexibility and efficiency.

The Future of Surface Cleaning

As laser technology continues to evolve, we can expect to see even more advanced solutions that are faster, safer, and more cost-effective. Innovations in laser cleaning will likely focus on enhancing automation, expanding material compatibility, and improving the portability of laser systems.

With its proven effectiveness and growing range of applications, rust-free laser cleaning is poised to become the industry standard for surface treatment.

Partner with RenovateRX for Advanced Laser Cleaning Solutions

RenovateRX is at the forefront of this technological shift, offering state-of-the-art rust-free laser cleaning services. Our expert team uses the latest laser technology to deliver top-notch cleaning solutions for a wide range of industries. Visit our Rust-Free Laser Cleaning page to learn more about how laser cleaning can benefit your business and transform your surface treatment processes.